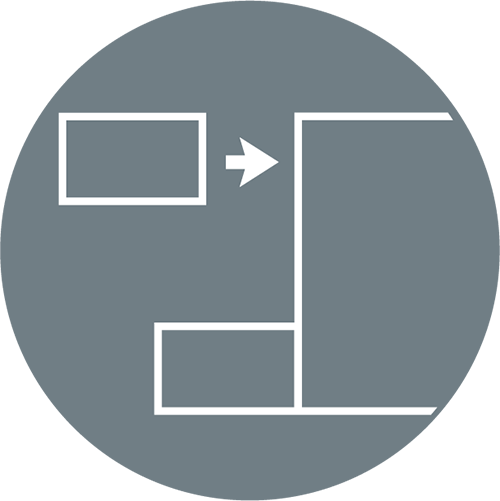

The edges of the plate are first planed parallel in the shape of a double Y bevel. Perfectly parallel and square edges as well as close width tolerances are essential for the forming operation. In addition, this is where the accuracy of the weld bevel and the quality of the seam are predetermined.

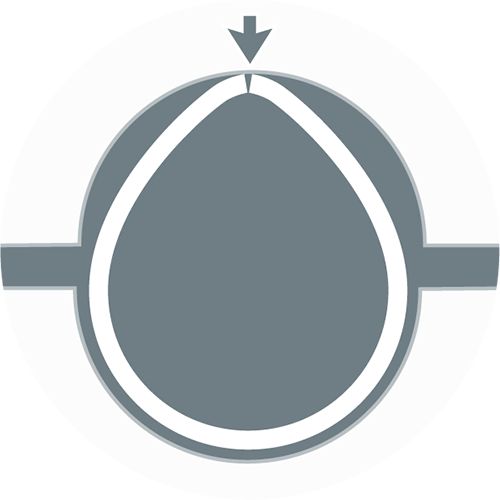

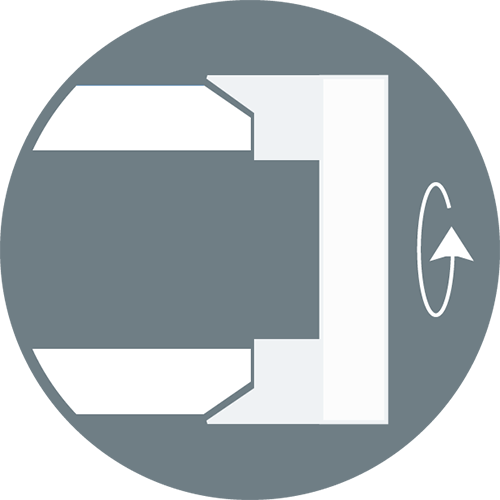

Over an area of approximately 200 – 400 mm, both edges of the plate are crimped simultaneously to the desired pipe radius. This operation ensures that the pipe meets even strongest requirements with respect to out-of-roundness, including the region of the longitudinal seam.

Our crimping press in Mülheim an der Ruhr / Germany is able to process plate thicknesses of up to 50 mm.

Before submerged-arc welding takes place, the open edges of the slit pipe are tack welded together under shielding gas.

This is done in frames (roller cages) which locate the edges exactly and prevent misalignment. The continuous tack weld also serves to retain the weld pool during subsequent submerged arc welding.

For identification each pipe is marked with a pipe production number.

Additionally a line, marking the centre of the pipe, is the reference for late non-destructive testing of the weld seam.

Inside welding is carried out first, followed by outside welding. The tack weld pass is completely fused. In submerged-arc multi-wire welding, up to five welding wires are arranged one behind the other.

Consistency of weld quality is determined by various parameters: Welding wire and flux, amperage, voltage, welding speed, wire spacing, wire diameter, the angle of the wires relative to one another and to the weld groove, as well as flux height and width. A welding data monitoring system permits online supervision of the production process.

First, each seam is checked visually, inside and out. Our internal quality checks also include ultrasonic inspection of the entire seam, which can also be augmented by X-ray examination and manual ultrasonic testing.

Image processing capabilities coupled with support by automatic image evaluation software significantly improve the reliability of inspection and detection compared with conventional film-based methods. Any ultrasonic indications are checked automatically and with pinpoint accuracy. We are proud to be the only large-diameter pipe manufacturer, that conducts all radiography tests with digital technology.

In parallel with the nondestructive tests carried out in the large-diameter pipe mills, the mechanical-technological properties of the base metal and the weld are measured in accordance with agreed specifications.

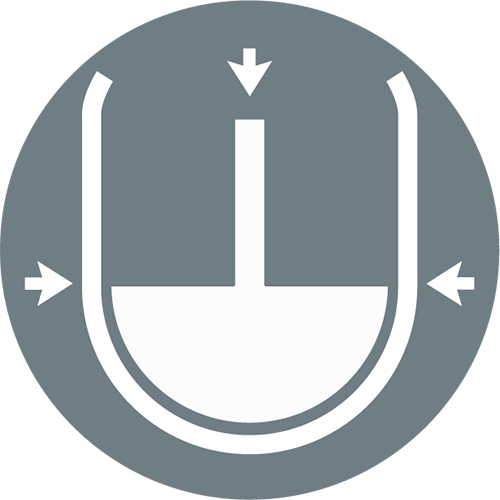

Pipes have to pass yet another demanding test while still in the mill: by means of internal water pressure, they are stressed close to their yield point – in other words, far above the operating pressures they will face in service.

The UT-device is a modern computer-controlled and fully automated machine with up to 10 probes for longitudinal and 4 probes for transverse testing with the latest water nozzle technology.

If required, internal and external surface inspection of the pipes can also be performed by magnetic particle inspection.

In a final step, both pipe ends are bevelled simultaneously in a single operation to ensure that the finished pipe ends are square and parallel for girth welding in the field.

The geometry of all pipe ends is fully automatically measured with pipe end measurement equipment based on optical laser sensors.

The laser measuring device checks the inside and / or the outside dimensions of the pipe ends according to the QA / QC instructions for this pipe. Basically the following dimensions are checked and recorded by PRODIS: diameter, roundness, circumference, wall thickness and peaking of all pipe ends.

Customer requirements on QA / QC are linked to the PRODIS system. PRODIS checks the results against the QA / QC requirements. Only pipes whose ends fulfil all requirements of QA / QC instructions will be released.

The pipe ends are non-destructively tested for laminations and inclusions by magnetic particle and ultrasonic inspection. Only perfect pipe ends permit defect-free girth welding in the field.

The final inspection includes additional checks of the entire pipe at diameter, wall thickness, bevel edges, roundness, etc. on the pipe body and ends.

Once all production and inspection steps have been carried out and all specification requirements have been fulfilled, the customer documentation is prepared. All results are listed, and certificates are produced.

This is another job taken care of by EUROPIPE's intelligent Production Control and Information System, PRODIS.