Quality is a global language

Our success is based on a very simple principle: To not just contribute ideas, but to think ahead. With this in mind each of our staff is dedicated to even more efficient products, better manufacturing processes, excellent service and an even more successful cooperation with our customers.

Our quality management system facilitates this process. It is based on the API Q1 and ISO 9001 standards, and all of our locations have been ISO 9001 certified since 1983. We can monitor compliance with these standards at any time, and implement improvements on the basis of objective measurements and audits.

We and our partners and suppliers fulfill the ISO 9001, ISO 14001, ISO 50001 and ISO 45001 specifications.

System Documents

> EMM, Process Descriptions

> QHSE Plans

> Procedures, Guidelines

> Quality Standards | Work Instructions

Documents Dependent on Customer

> Customer Specifications

> Manufacturing Procedure Specifications (MPS)

> QA / QC Instructions

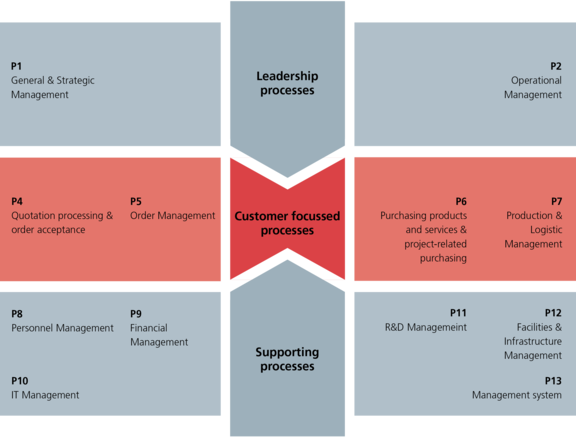

EUROPIPE Management System / QHSE

The oil and gas pipeline market requirements are extremely challenging. In order to fulfil and exceed these, EUROPIPE operates a fine-tuned value chain, from molten metal to the final coated pipe, delivered on time and on specification, anywhere on the planet.

All relevant QHSE activities in this value chain have been analysed and documented. The resulting comprehensive set of process descriptions, plans, procedures, guidelines and the EUROPIPE Management Manual (EMM) describe the EUROPIPE Management System. It forms the basis for all activities in our company and interactions with our customers. It assures that all client-related product and manufacturing specifications are reflected in detailed QA/QC instructions and that these match the relevant work instructions and quality standards of the EUROPIPE Management System. This guarantees that all client related processes result in a successful project and sustainable business activity.

Our quality management system is based on the standards API Q1 and ISO 9001. EUROPIPE has held ISO 9001 certification at all locations since 1993. This means that at all locations the processes are planned, carried out and documented according to the same, binding set of standards. We can check compliance with these rules at all times. Any necessary improvements can be undertaken based on objective measurements and audits in addition to our extensive operational experience.

Basic Principles

The EUROPIPE Quality Management System is based on the following principles and benefits:

EUROPIPE is part of an integrated production chain, from steel-making to pipe coating. EUROPIPE purchases pre-material as well as operational resources from qualified suppliers.

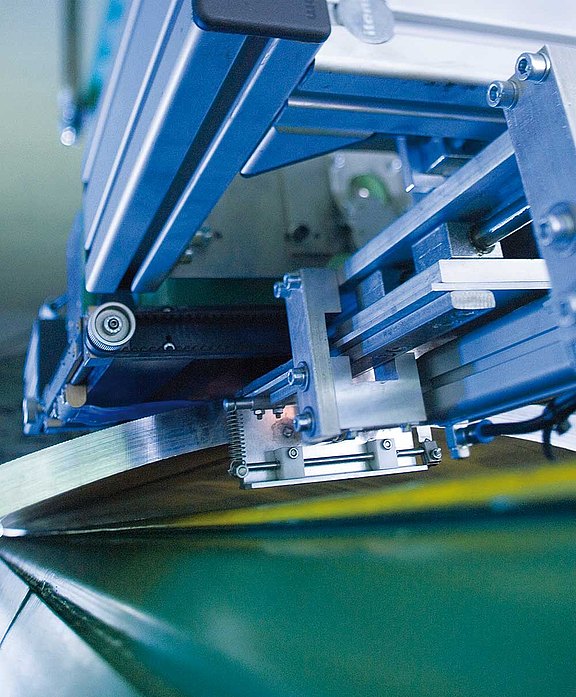

EUROPIPE products are manufactured and inspected with state-of-the-art computer support as well as automated control of production and transport processes. This allows for a constant high level of quality and complete traceability of every product.

Data retrieved by the automated control system is used for documentation and statistical analysis. It makes an essential contribution to the continuous improvement of EUROPIPE processes.

Compliance with deadlines is ensured by an integrated production planning system and supply chain management.

EUROPIPE integrates both customer requirements and market developments into its extensive product development activities. Furthermore, EUROPIPE continuously invests in the improvement of production, inspection and testing processes.

EUROPIPE gives highest priority to the health and safety of its employees, contractors and customers. The main aspects of the health and safety system are:

The promotion of health and well-being of our employees, mainly through the health initiative “leben! – Einfach gesund” (life! – Simply healthy), a programme which is adapted to the particularities of the pipe production business. It enables all employees, no matter what shifts they work, to use a broad network of sports clubs, company physicians and caterers at low cost. This holistic concept combines sports programmes, preventive medical check-ups, nutrition topics and informative events.

Avoiding of work-related sickness through various programmes focussing on creating individual ergonomic workplaces, especially man-machine interfaces.

Prevention of accidents through programmes informing staff about correct behaviour and possible hazardous situations, as well as programmes in which all employees actively participate and contribute their ideas on how to avoid accidents.

We ensure for occupational health and safety by:

Making occupational health and safety a management responsibility.

Identifying risks in all areas of the company and taking preventive action (including emergency plans).

Requiring our employees to actively promote and support occupational health and safety for their own sake and for the sake of others.

Defining occupational health and safety rules in relation to the places of work; our employees and third-party inspectors are continuously made aware of these rules and receive regular instruction.

Making reserves required for the purpose of occupational health and safety an integral part of our planning in order to ensure optimum working conditions and provide each employee with personal protective equipment.

Regularly reviewing the efficiency of our occupational health and safety system, establishing statistics and communicating information about the current situation.

Encouraging our partners and suppliers to implement similar occupational health and safety systems.

Our goal is to minimise the burdens our business activity places on the environment. Therefore, we have committed ourselves to the following guidelines:

Compliance with relevant environmental laws and regulations is the basis of our operational decisions.

It is our aim to motivate our employees to take care of the environment. We inform and train employees on all levels and increase their awareness of environmental protection as part of their day-to-day business.

Our production is orientated towards spending resources sparingly, reducing the generation of waste and wastewater through closed circuit management, and preventing emissions escaping into water, soil and air. To this end, we employ the best technology available.

By selecting appropriate raw materials and supplies, pollution levels of waste and wastewater are to be minimised as far as possible.

In order to prevent and control events that could have an impact on the environment, we have implemented an emergency response system.

Every manager is convinced that environmental protection is an indispensable component of our management system.