Collaboration with added value

Our strength lies in strong partnerships. Together with shareholders, research institutions and industry partners, we develop innovative solutions for the energy and water infrastructure of tomorrow.

Our shareholders are also pioneers in the field of greenhouse gas-reduced steel. Thanks to this raw material from the electric steel route, which reduces CO₂ emissions by over 70%, we can also offer GHG-reduced pipes that not only meet the highest technical requirements but also make a significant contribution to the transformation of pipeline projects. Our Carbonlite pipes, with a CO₂ reduction in production of currently over 70%, are also ‘ready for H₂’ and therefore perfect for the energy transformation.

Research and development – innovation as a driving force

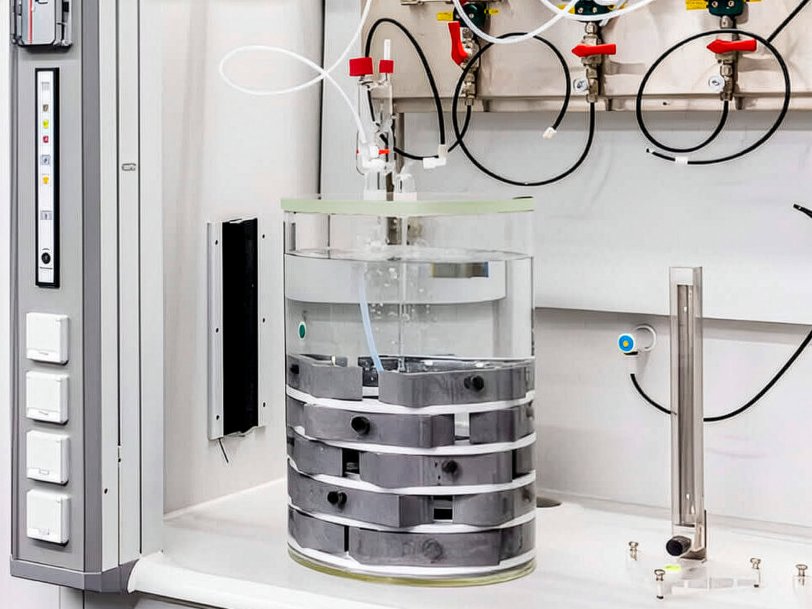

Our ability to innovate is a key component of our success. Collaboration with leading research institutes is a matter of course for EUROPIPE. Salzgitter Mannensmann Forschung – our centre of excellence for research and development – coordinates close cooperation with universities and scientific institutions. All of the institute's laboratories are accredited and guarantee the highest quality. Together with customers and suppliers, we continuously develop existing products, processes and services and create innovative solutions for the energy and infrastructure sectors.

Pre-material – the basis for quality

The basis for our large-diameter pipes is the steel supplied by our shareholders, AG der Dillinger Hütte and Salzgitter Mannesmann GmbH. At the sheet rolling mills in Dunkirk (France), Dillingen an der Saar and Mülheim an der Ruhr (Germany), steel slabs are rolled into high-quality heavy plates using a thermomechanical process – with ideal properties such as stability, durability and weldability. This enables us to create the best conditions for pipes that are used worldwide under the toughest conditions.

Pipe bending technology – precision from Mülheim

For decades, the pipe bending plant at Salzgitter-Mannesmann Bending plant on the factory premises in Mülheim has been forming EUROPIPE pipes into pipe bends and supporting our production with world-class pipe bending performance. With wall thicknesses of up to 100 mm, pipes are precisely hot-formed using inductive heating. This process enables maximum flexibility and quality – and expands the range of applications for our pipe solutions for a wide variety of projects.